Dependable Digital Die-Cutting Services

Do you need printed graphics, prototypes, or signage? Are you in need of a short run project made from thin or plastic material? ? The only thing that can help you deliver an amazing print and shape to your clients, customers, or partners is die-cutting. Even if you have a creative concept that seems borderline impossible to print and cut, digital die-cutting can help.

In our efforts to deliver the best digital die-cutting services to you, we have invested in the industry’s most state-of-the-art equipment and job processing software. Hopkins Printing has been offering digital die cutting services for over 18 years and is home to the highest quality and most cost-efficient die cutting machines in the country. Whether you need to die-cut one, or thousands of pieces, we are here to help you out.

What is Digital Die-Cutting?

Digital die-cutting is a finishing method similar to steel-rule die cutting but uses no cutting dies and requires minimal setup time. The cutting process is done by a machine that drags a metal blade through a material that follows a digital vector file converted into XY coordinates.

Digital die cutting equipment processes a vector file by reading points along a path and moving the machine cutting head location to mirror the path. The machine moves the cutting blade using a beam that is suspended over the top of the material. The beam moves in one dimension (X) while the mounted cutting head and can move along the beam (dimension Y). Further controls allow the cutting head to move up and down per task assigned which controls the depth of the cut (dimension Z).

Depending on the task required, there are several cutting tools and blades. A drag knife tool is best for cutting magnet, paper, or thin polystyrene while a reciprocating tool is ideal for foamboard and cardboard materials. Additionally, at Hopkins we use crease wheels, routers, and kiss cut tools depending on the task and material required.

Digital die-cutting is famously ideal for thin or flexible materials like paper, magnet, polystyrene, or decal vinyl, but with the right tooling it is also a great option for corrugated, foamboards, and countless other options. At Hopkins Printing, we routinely use our digital die-cutting equipment for cutting :

- Instore point of purchase display graphics

- Retail signage

- Vinyl cut letters

- Oversized graphics

- Intricate shapes

- Kiss cut projects

- Tight tolerances

- Templates

- Short run projects

- Custom cartons

Digital Die-cutting Vs. Traditional Steel Rule Die-Cutting

While the principle of either cutting method is the same (forcing a blade through a material), but the technique is different.

Traditional Steel Rule Die Cutting

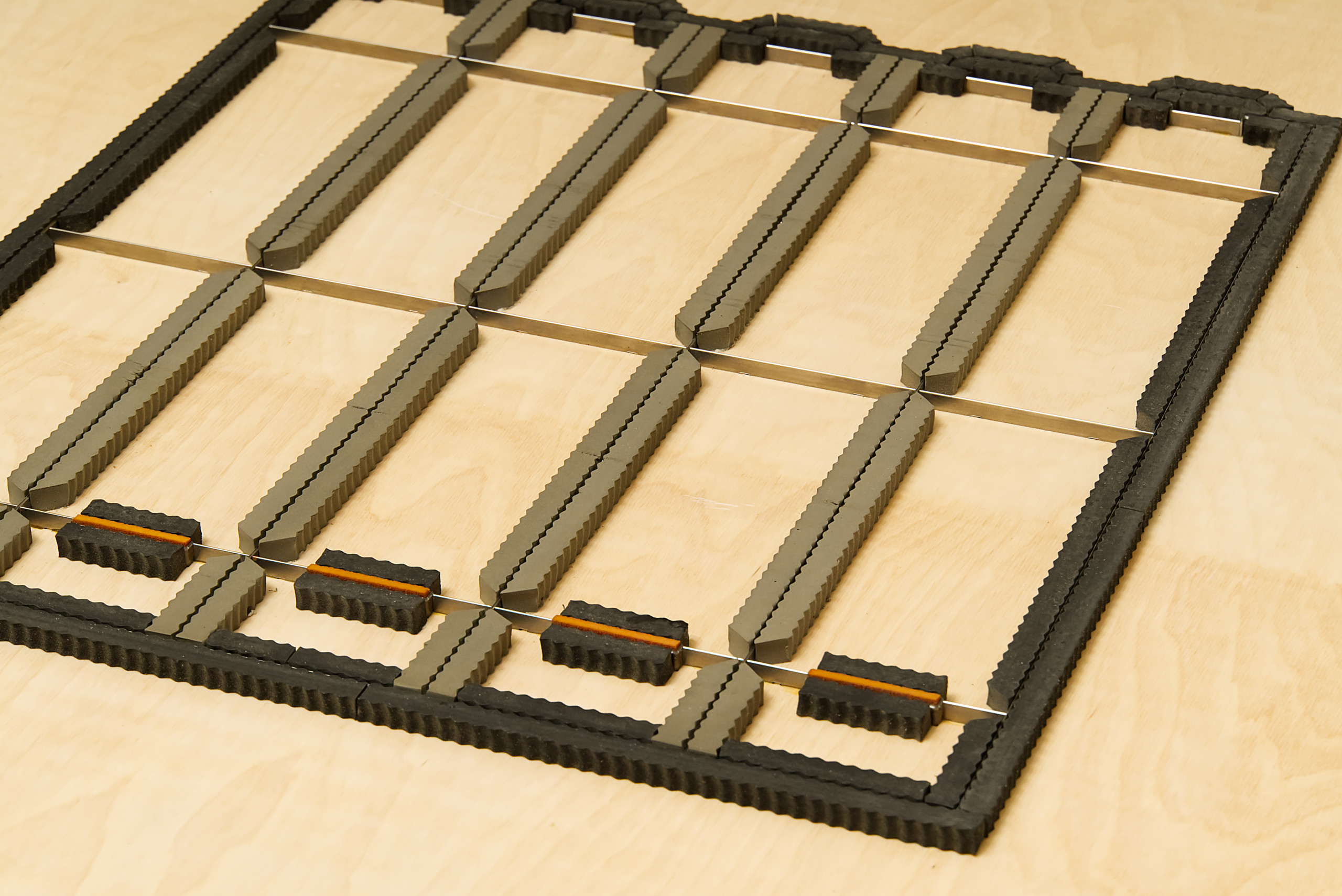

Steel rule die cutting uses a thin long fixed steel blade that is custom bent to a desired shape by a die maker and fit into tight channels cut into a wood board from a jigsaw or laser. Similar to an ink stamp, the die is now custom made for that job with high impression points. It can be reused, as long as nothing changes. When the die is compressed on a softer material, the long custom bent blade is forced through the material all at once cutting the entire impression at once. Once cut, machine opens up and the cut sheet is replaced with a new one. To maintain registration, the die must be secured in place and new sheets must be loaded into guides. Registration cannot be easily checked prior to cutting the entire sheet which forces companies to demand a surplus of over run to achieve the needed quantities.

Advantages of Steel Rule Die Cutting

- Speed – Once setup, cutting speeds can exceed 500 sheets per hour

- Cost – Due to speed, the labor cost can be made lower than digital die cutting on very large production runs

- Repeatability – Each part is cut from a fixed template die that cannot change.

Steel Rule Die

Digital Die Cutting

Digital die cutting on the other hand uses a small blade that is pushed down into the material and is pulled through the material along a cutting path. This motion is done with precision accuracy due to the use of electronic servo motors in each of the x, y, z dimensions. Because there is one small blade traveling around the vector path, the cutting process varies from job to job based on how long the path is and how many times the blade needs to lift and turn. A die line of a single circle can be processed in seconds while cutting a more complicated die line of 40 nested wobbler shelf talkers may take minutes. The advantage is that there is no upfront cost or wait time to make a die. The job can be processed in minutes and changes can be made with a click of a button.

At Hopkins Printing, our machines are equipped with optical cameras that read the printed registration marks on each sheet prior to cutting. Each sheet is registered and the machine automatically moves the die line to compensate for differences to make all output look identical. This isn’t possible with a fixed traditional die. To speed up the machines further, they are also equipped with conveyor feeding to minimize down time. When one sheet is complete, the machine automatically advances the next sheet and begins processing it.

The largest technological advancement in digital die cutting in the past 20 years is processing jobs with two cutting heads instead of one. The Zund D3 software analyzes the entire cut file and the algorithm assigns each cutting head to certain parts of the file to finish it in the most efficient way possible. Each cutting head is mounted on a separate beam and they operate independently of each other as if it’s 2 machines built into one. This new advancement is unique to the Zund D3 machine and can reduce cutting time and costs by half, making it more competitive to traditional steel rule die cutting.

Advantages of Digital Die Cutting

- Registration – Each sheet is optically read and the cutting is moved to match perfect with the print placement

- Quick to press – No waiting for a die fixture to be made. Jobs can be cut within minutes of releasing a cut file

- No die charge – No upfront die fixture cost

- File changes – Changes to die line are easy

- No storage needed of die

- Large format sizes – Capable of cutting large format sheets and rolls. Sizes can be nearly infinite in one direction

- Versatile – Many tooling options for variety of materials and can offer superior cut quality

- Quality control – Each sheet is handled and seen by the operator providing more opportunities to catch issues

- Cost – With no die fixture and fast setups, the cost is often more effective for small to large runs

- Details – Tiny and intricate shapes are possible where traditional bent steel blade may not be

While both cutting methods have their place, steel rule die cutting’s largest advantage is speed on extremely large production runs. In most other cases, digital die cutting is a superior

How Does Digital Die-Cutting Work?

Digital die-cutting starts with a vector based design file from programs such as Adobe Illustrator, InDesign or AutoCAD. . A cutting file is created in these programs by making a vector path for the machine to follow. There can be a single or multiple paths for the tool head to follow.

Before sending the job to our digital die cutter, each vector paths will be separated into layers and labeled based on the task required. Tasks such as perforating, creasing,kiss cutting, holes, thru cutting, and routing would be normally separated into separate layers. Digital die cutters come with hundreds of unique blades and parts to ensure that even the most complex designs or bizarre materials can be cut. After layering,labeling, and assigning machine settings to each our digital die cutter will process each layer at a time bringing your design to life.

The Benefits of Digital Die-Cutting

Digital die-cutting is the best thing technology can offer at the moment. It delivers a variety of benefits. Here are the most noteworthy ones.

Versatility

Digital die cutters are very versatile. They can cut through a variety of materials. Whether you need something created out of paper cardstock, magnet, foam core, sandwich board materials, polystyrene plastic, or pressure sensitive decal vinyl , you can rest assured that you will get the job done.

Flexibility

Some design concepts can be very complicated, making you think they are not suitable for digital die-cutting projects. Digital cutters feature hundreds of unique blades and bits. They can cut every shape that a designer can imagine and then some. You can bring the most challenging designs to life and make your brand stand out from the crowd.

Great Precision

Thanks to finely tuned servo motors, optical camera registration, and specialized tools such as crease wheels, kiss-cut modules, routers and reciprocating -tools, Hopkins Priniting’s digital die cutting equipment has a machine repeatability spec of +/-0.03 mm and a positional accuracy of 0.1 mm/m + repeatability.

Reduced Production Costs

Due to automation and fast and easy adjustments, digital die-cutting (especially on Hopkins Printing’s Zund D3) is cost-efficient. This is extremely important for budgeting large projects and cutting hundreds or thousands of pieces. Digital die-cutting services deliver the best price-quality ratio.

If you want to find more about digital die-cutting, feel free to contact us today! We are more than happy to answer your questions or provide you with a quote for your die-cutting project.