Digital printing vs. screen printing: While there’s no question wide format UV digital printing has some clear advantages – including producing wide format sizes, high resolution images, consistent output, and ease of printing small quantities – there’s a lot to be said for screen printing, despite it being a process that’s hundreds of years older.

Here are just a few of the reasons you may want to select to have your project screen printed instead of digitally printed for your next signage or printing project:

Wider array of unique color offerings

Perhaps the biggest advantage screen has over digital is the ability to print custom mixed spot colors. This comes as a surprise to some of our customers, but generally speaking, digital printers are limited to four options on the color spectrum: cyan, magenta, yellow and black, or what’s known in the industry as CMYK,which limits the colors possible. Screen is capable of recreating pretty much any hue that you can imagine, and will do it impressively, because the ink layers tend to be thicker, richer and more vibrant. They’re also not bound to the CMYK color spectrum. Clear, white, neons, and vibrant colors in general are possible with screen printing. Printing custom mixed inks look sharp and clean also compared to any CMYK process color mixture.

Of course, the combining of CMYK in selected ratios with digital printing makes it possible to print in a plethora of shades, but the variety isn’t quite as extensive as it is with screen printing. Be it fluorescent, metallic silver or rusted gold, these colors and much more are reproducible via the screen printing method.

“Less time and ink equals lower costs for our customers.”

Less ink, less cost

As you might imagine, the amount of ink used in each project is rarely the same from one to the next. In general, though, the run costs for screen printing tend to be more affordable. This is partly because some jobs may require only one or two colors which is a lot less ink usage than digitally printing four or more colors. Also, screen printing inks are a fraction of the cost of custom formulated OEM digital printing inks, which you’re probably familiar with when buying ink for your desktop printer.

In addition, labor and press time are large factors in the cost of any job. There is no denying that digital printing is the best option for short run jobs, but as the projects get larger and require more press time, screen printing can be more favorable due to the printing speeds. Less time and ink equals lower costs for our customers. And there’s a lot to be said for that when you’re operating on a deadline (as many of our regulars tend to be).

The Home Depot, Lowe’s, Best Buy and Rite Aid are just some of the clients we’ve produced signage for over the years. These retailers have multiple locations throughout the country, so they often need work done for many stores at once.

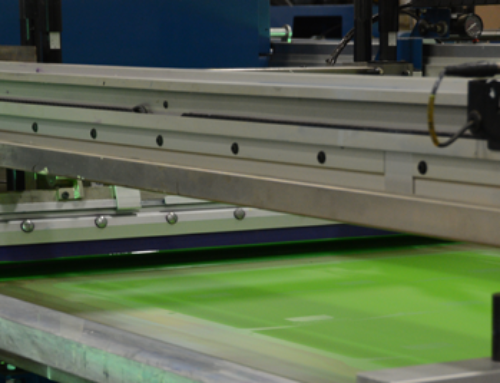

For large jobs such as these, screen printing may be the better option from an efficiency and timeliness standpoint. Our M&R Processor can print over 250 sheets per hour that measure 60″ x 84,” which equates to over 8,700 sheets per hour. This isn’t to suggest that digital shouldn’t be considered, but all things being equal, screen printing makes a lot of sense for extensive projects by keeping costs under control and producing more quickly. Timing really is everything for seasonal sales events or biannual campaigns.

Greater versatility

Vinyl, Coroplast, plastics, wood, metals: You name it, there’s a good chance we can print on it. Advancements in adhesion, equipment, strategy and technology have helped make printing on a host of materials possible. However, some materials are better than others for boldly displayed lettering, coloring and shading. And in most cases, screen printing provides a better variety of ink versatility.

This is particularly true for Coroplast, one of the more common materials we see for projects. While they’re best for short-term usage, Coroplast – otherwise known as plastic cardboard, or corrugated plastic – can be used both indoors and outdoors. However, projects that call for this material usually are in need of an inexpensive rigid material in large quantities. Examples are yard signs and campaign signage. When these projects come up, screen printing is the usually the clear solution for our clients.

Additionally, ink adhesion can be an issue for all print suppliers and printing on plastics is never easy. There isn’t a perfect ink formula that adheres to everything and works in all scenarios and digital printing inks aren’t easy to swap or customize like screen printing inks are. When screen printing, if the formula isn’t working as needed, the operator has the ability to add custom additives included in the ink formula to make the inks more flexible or bond better. This makes unique projects and hard-to-adhere surfaces better solutions for screen printing.

Screen printing deposits a thicker layer of ink during production.”

The same can be said for the weather-resistant element of screen printing ink. While both screen and digital utilize UV ink, which is custom designed to be used on a number of different materials and applications, screen printing deposits a thicker layer of ink during production, which results in more pigment on the material keeping the colors vibrant longer.

There’s no denying that the world – printing included – is more digital than ever. But make no mistake, screen printing isn’t going away. It’s here for the long haul for these reasons and many more. If you have questions about which you should choose, talk to us at Hopkins Printing. We’ll recommend the method that makes the most sense for your needs, budget and goals.