It’s important to have the right vocabulary when selecting a potential printing partner. Knowing terms like prepress, file format and process color helps you ask the right questions and fully interpret the answers. This brief glossary will help you get up to speed so you know exactly what questions to ask:

1. Digital printing

This modern printing form transfers an image directly from a computer onto a substrate without the use of additional tools such as custom plates or screens. The majority of digital printing is done using inkjet nozzles that spray microscopic droplets of cyan, magenta, yellow and black in a particular pattern to make the desired print. Digital printing features many advantages such as minimal waste, great resolution on process images, fast setup times, quick turnarounds. As Business2Community pointed out, digital printing can duplicate nearly any type of graphic.

2. File format

This term defines how your graphic is encoded on a computer. Common file formats for printing include PDF, TIFF, EPS, AI, PSD and INDD. The latter three are specific to Adobe Illustrator, Photoshop and InDesign. JPEG, GIF, BMP and PICT are also common file formats, but these are generally unsuitable for printing. PDF files are generally preferred and universal and carry more information within the file.

3. Prepress

This describes the stage between the finished artwork and the start of the printing process. Prepress includes determining the job layout, trapping colors, color matching and proofs, adding a cutting pattern, selecting the best substrate and more to make sure that the artwork prints as desired. A printing partner that offers prepress services should also help you complete any final touches to your artwork.

4. Process colors

This color-matching method, used with digital printers, breaks the colors of a graphic down into four hues known collectively as CMYK: cyan, magenta, yellow and black. During printing, tiny dots of each color are applied next to each other to create the illusion of a single shade.

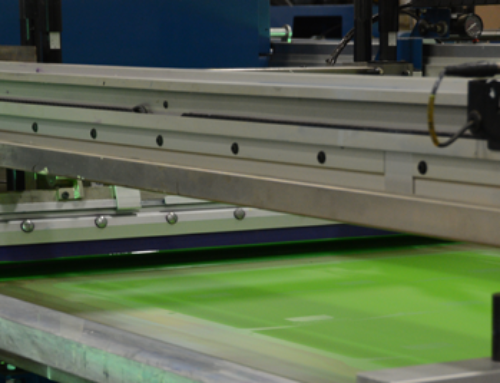

5. Screen printing

This 4,000-year-old printing process, so named because it originally involved silk screens, uses mesh to place ink in specific areas on a substrate. Screen printing is done one color at a time and requires a separate screen per color, making it economical for larger jobs. However, screen printing provides excellent color matching and is generally faster than digital.

6. Spot colors

Spot colors are created by blending two or more solid colors together, similar to how mixing red and blue creates purple. This color-matching process is used for screen printing – the color is premixed and the ink is poured onto the screen template. Spot colors allow your printer to match the exact hues of your original artwork. If, for example, your logo is a particular shade of purple, this matching process can recreate it exactly.

7. Substrate

This is a general term for the surface on which your graphic will print. A good partner is versatile and can print a wide variety of products – including POP graphics, aisle markers, yard signs and more – on a surface suitable for your project. In the retail signage and POP graphic market, common substrate materials are polystyrene (HIPS), expanded PVC, paper cardstock, foamboard, PETG, acrylic, polyester (PET), Lexan/polycarbonate, magnet, fluted plastic (Coroplast), and cardboard. All substrates offer different properties. Ask an NGS representative to help select the material that best fits your needs.