From vinyl to acrylic, Komatex/Sintra to foamboard, printing materials today come in a wide assortment of styles and profiles to portray the images, pictures, phrases and logos that turn heads. Here at Hopkins , you name the media, there’s an excellent chance that we print on it.

However, there’s one material in particular that’s our bread and butter. In fact, this substrate accounts for roughly 30% of everything we print on and is something you see every day, even though you may not realize it. It’s called polystyrene, and no matter what you want your signage to convey, polystyrene can do it and then some.

Polystyrene is among the most frequently used plastics in the world.”

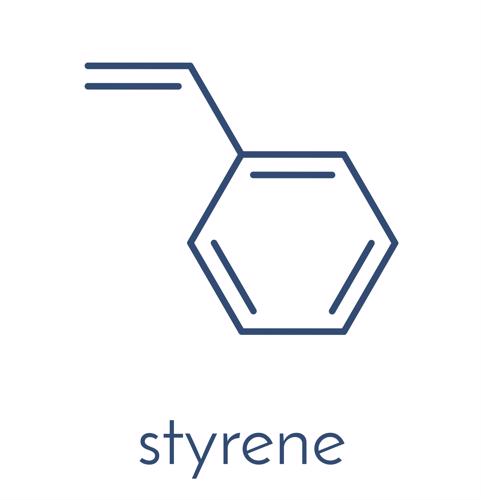

What is polystyrene?

Often referred to as simply styrene or HIPS – the HI referring to “high impact” – polystyrene is among the most frequently used and manufactured plastics in the world, found in a wide assortment of products, such as assembly kits, license plate frames, disposable cutlery, razors – and even smoke detector housings. Where’s it’s particularly commonplace is point-of-purchase signage. Whether it’s hung from a ceiling as a hanging poster, made as an aisle violator or as a printed panel for a fixture display, POP signage is likely cut from HIPS material.

Why is high-impact polystyrene so ubiquitous? The reasons are far too numerous to mention, but here are a mere handful of them:

1. Robust

Styrene is a solid material without fillers like foams, flutes, or puffing agents to add rigidity or thickness. As its title suggests, high-impact polystyrene is quite sturdy and resistant to a wide assortment of environments that can result in wear and tear. As noted earlier, this material is the very definition of multifaceted and helps preserve items that aren’t as resilient. That’s why it’s often used for packaging, as it is resistant to moisture and can be surprisingly rigid at thin gauges like 0.040″ and 0.060″ thickness while being flexible enough at gauges like 0.015″ and 0.020″ that it can be rolled. This is also what makes it an ideal media to print on for graphical display purposes in both screen printing as well as digital printing.

Styrene becomes high-impact once it’s mixed with various additives, which strengthen its composition and endurance. This makes it a great deal easier to work with in terms of fabrication as well as for signage use. Styrene is ideal for semi-permanent and permanent point of purchase displays because it is resistant to tearing, stains and dents. Retailers and fixture designers don’t need to worry about customers damaging the graphics. Given this, in addition to more vividly portraying whiter whites and brighter brights, polystyrene signs can come in various thicknesses without compromising its tensility.

3. Print Appearance

Polystyrene is favored in the print industry for its smooth surfaces and its nice finish. Smooth surfaces always make prints look sharp and small text is easy to read. Styrene also has a consistent white point instead of yellow hues that expanded PVC or papers tend to have, which makes any image printed look true and vibrant.

4. Highly customizable

High impact polystyrene for printing is available in many thicknesses and at Hopkins Printing, we most commonly see 0.015″, 0.020″, 0.030″, 0.040″, 0.060, 0.080″, 0.100″, 0.118″ and more! Further styrene is available in opaque, translucent, white, black and custom run in a particular color as well as a host of other specialized compatibilities. There is even a grade of styrene that has air added into it so that it is light, cheaper to ship and – more importantly – cheaper because there is less styrene needed to make the sheet.

5. Budget friendly

Styrene pricing is based off of weight and because it’s a dense product it can sometimes be expensive when compared to alternative white rigid materials like expanded PVC or foamboard that have filler or air added. However, there aren’t many print friendly options that offer all of the attributes that HIPS has. While styrene may sometimes be more expensive to purchase as a raw material, it is easier to work with in printing and finishing which can lead to a lower final cost. In the end, it’s about what look you’re looking for and HIPS offers a beautiful final product.

When it comes to impressive signage that performs – and at the right price – polystyrene may be just the solution. Here at Hopkins Printing, we’re ready to serve you for all your signage needs, HIPS and otherwise. Contact us – we’ve got the experience and display manufacturing capabilities that can get your company, campaign or announcement noticed.