Automation is one of the biggest buzzwords in the world of business today, regardless of industry. In the printing world, the term usually means streamlining the prepress process so your job is completed faster and more efficiently along with adding machinery so less human intervention is required. You might not realize it, but automation in the printing industry helps your business greatly. Here are two ways how:

1. It helps us meet your needs and expectations

Run lengths are shrinking across the industry. This isn’t necessarily a bad thing- as Screen Printing magazine indicated, shorter runs reflect the desire for more customized solutions. Fewer companies want hundreds of POP graphics to appear in stores across the country. Rather, they want smaller, more unique runs tailored to particular regions – or even individual stores. This reflects the current marketing trend toward personalization, even in offline marketing. Research from Econsultancy and RedEye, published on eMarketer, found 95 percent of marketers who added offline personalization to their methods saw higher conversion rates.

Automation allows us to address these unique requests faster than we’d be able to otherwise.

At Hopkins , we’ve invested in software automation within our prepress department to react to the growing trend in personalization. Today, our software will automatically step out a piece of art of a particular quantity, nest them on the sheet to the most economical manner to save waste, send a PDF proof for approval, and rip the file to the printer and cutter without human intervention. What formerly took 30 minutes is now taking five, which allows us to better react to smaller runs and keep our digital printing equipment running.

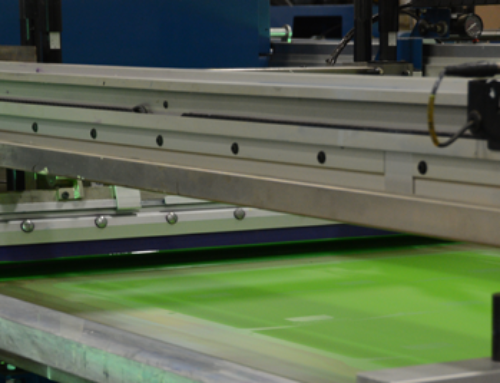

In addition to software automation, Hopkins has invested in semi-automated machinery as well to help reduce turnaround times. At Hopkins , our Inca Onset Q40 features 3/4 automation which, per the manufacturer, increases output by up to 50 percent. 3/4 automation is an automated sheet feed and automated sheet take off but simply requires the operator to place the sheet into preset guides. Also, Hopkins uses several versatile digital finishing tables that can router, die cut, or crease using optical registration which is great because the parts come out perfect every time. These machines use conveyors, sheet feeders and feature software that automatically import and setup the cut file. These small advancements all help us react quickly to the continued path of short runs and fast turnarounds.

2. It helps us get your prints more accurately

All humans make mistakes. Mistakes can happen at the point of writing down the print instructions, to forgetting to assign PMS colors to the print file, to feeding the sheet incorrectly in the press, to counting the amount of parts are in a box; but the more automation that we introduce into our process, the more accurate the process becomes. As Printing News pointed out, automation saves time by eliminating mistakes.

“Automation removes the error prone touch points of a print manufacturing process, thus delivering more consistently correct output,” Todd Viniski, worldwide marketing manager for Xerox, told Printing News. “Better asset utilization, combined with less process errors, means more is getting done in less time, driving total cost down.”

By automating our prepress process, Inca Onset printer and finishing equipment, Hopkins is able to deliver the quality, customized print solutions you need in a fraction of the time. Automation is just one way we dedicate ourselves to being the perfect printing partner for your business.[/fusion_builder_column][/fusion_builder_row][/fusion_builder_container]